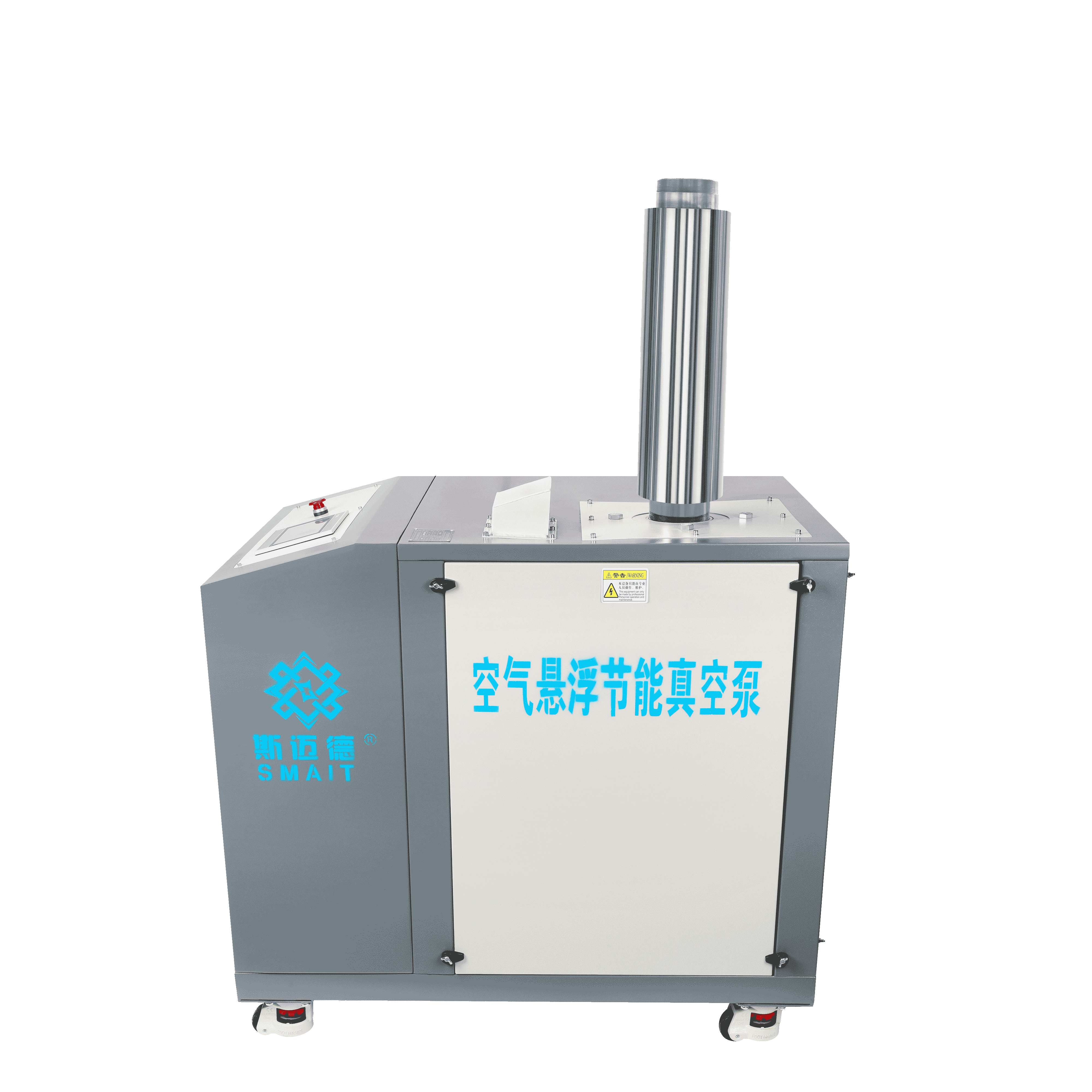

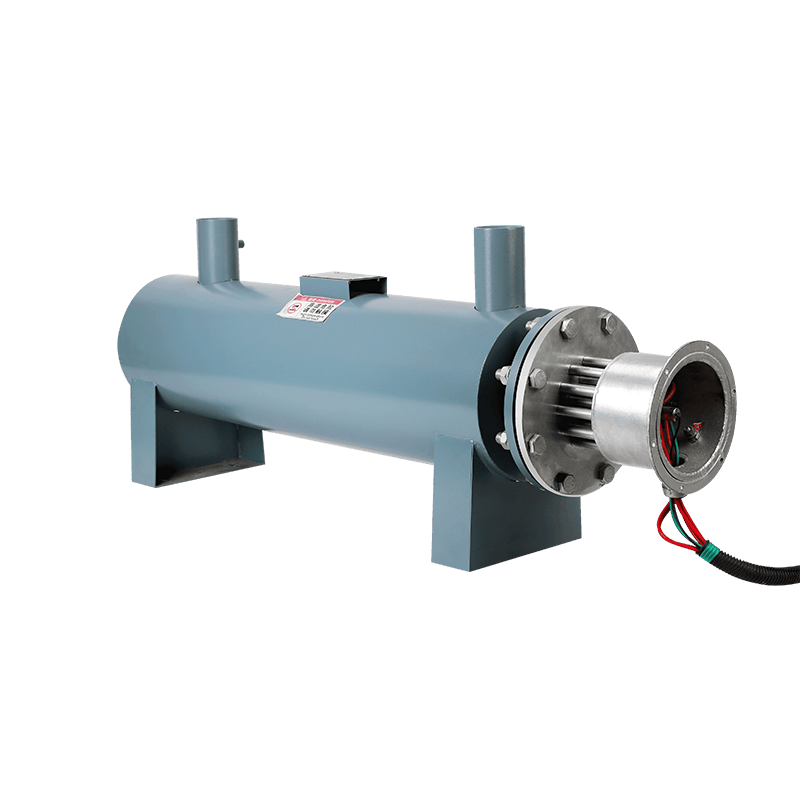

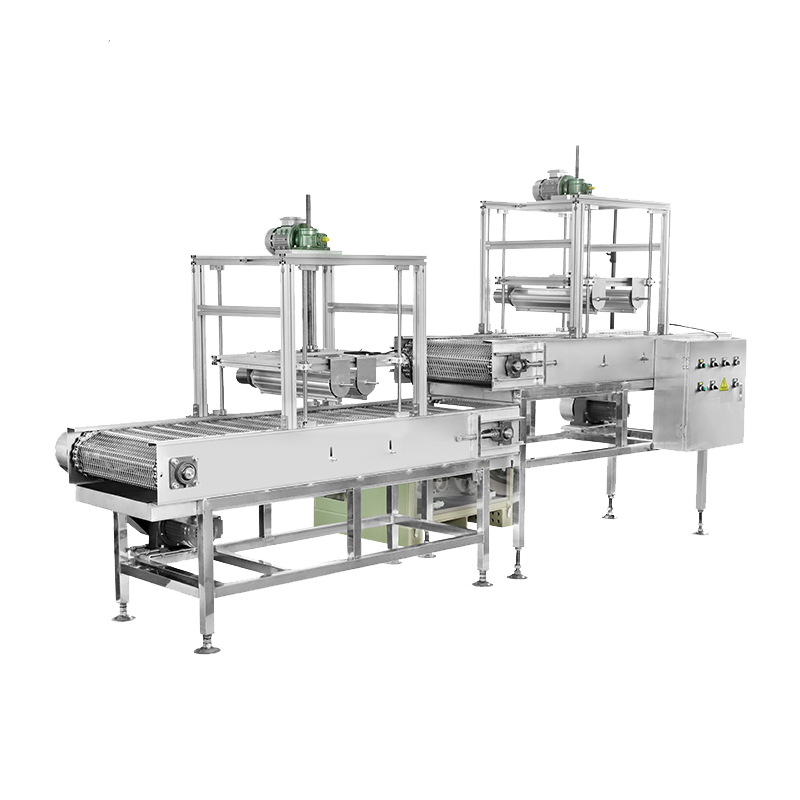

Mesh belt drying production line

Wechat consulting

Details

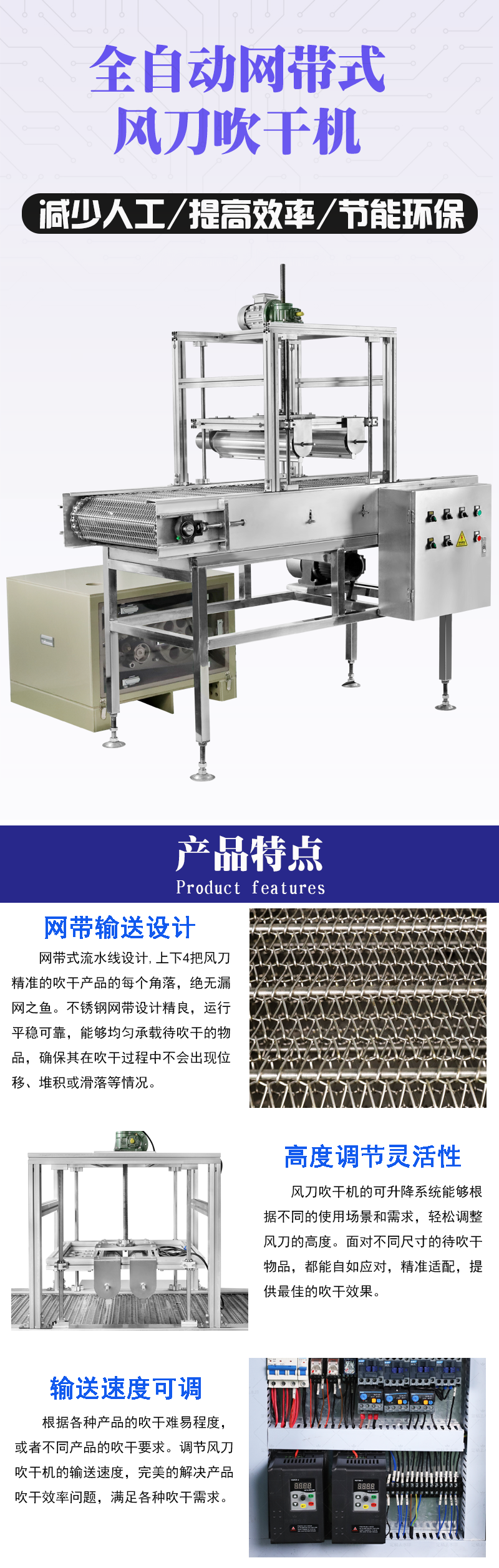

Performance characteristics:

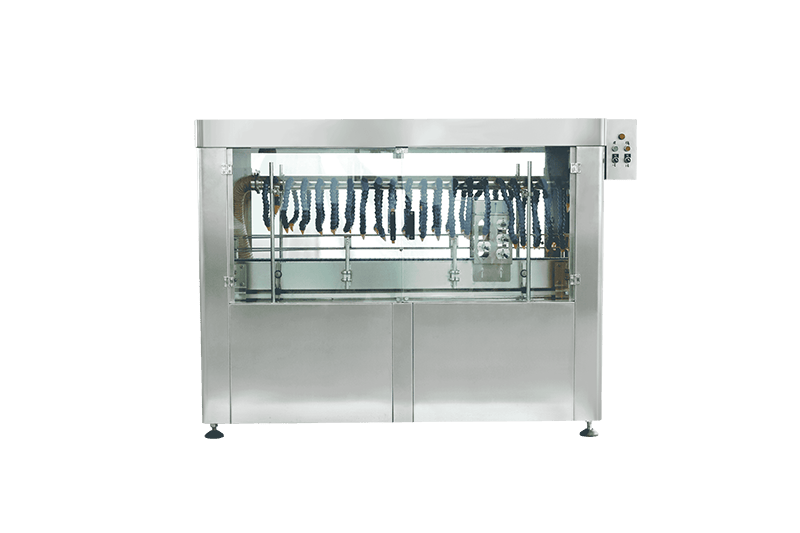

1. Mesh belt assembly line design, with 4 air knives at the top and bottom to accurately dry every corner of the product, without any fish leaking through the net. The stainless steel mesh belt is well-designed, runs smoothly and reliably, and can evenly carry the items to be dried, ensuring that they are dried during blowing

There will be no displacement, accumulation, or sliding during the process.

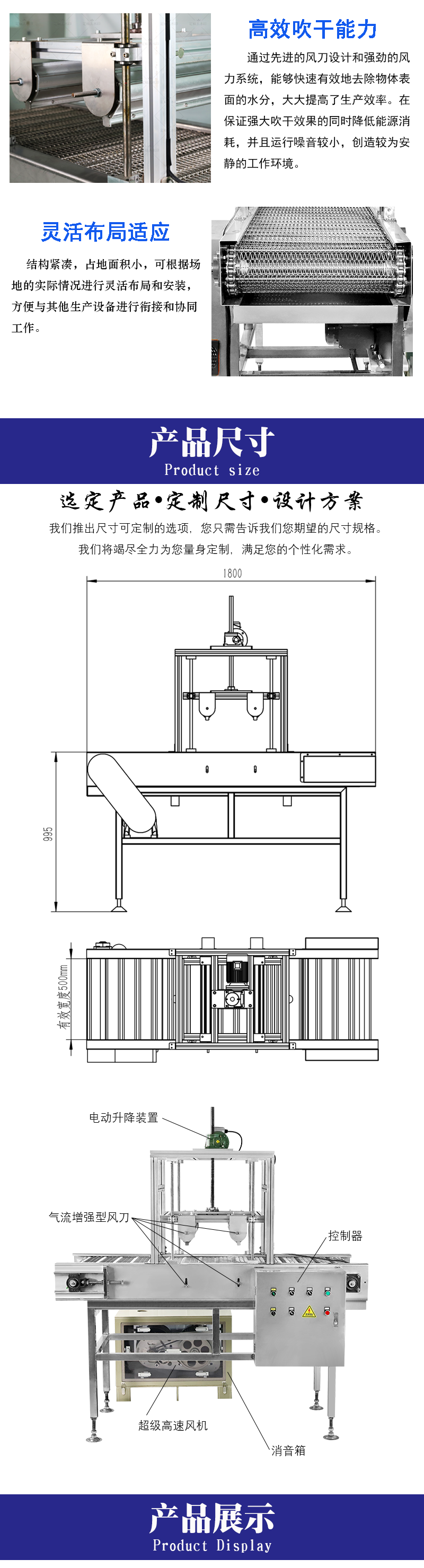

2. The adjustable lifting system of the wind knife dryer can easily adjust the height of the wind knife according to different usage scenarios and needs. Facing different sizes of items to be dried, it can handle them with ease, accurately adapt, and provide the best drying effect.

3. According to the difficulty of drying various products or the drying requirements of different products. Adjust the conveying speed of the air knife dryer to perfectly solve the problem of product drying efficiency and meet various drying needs.

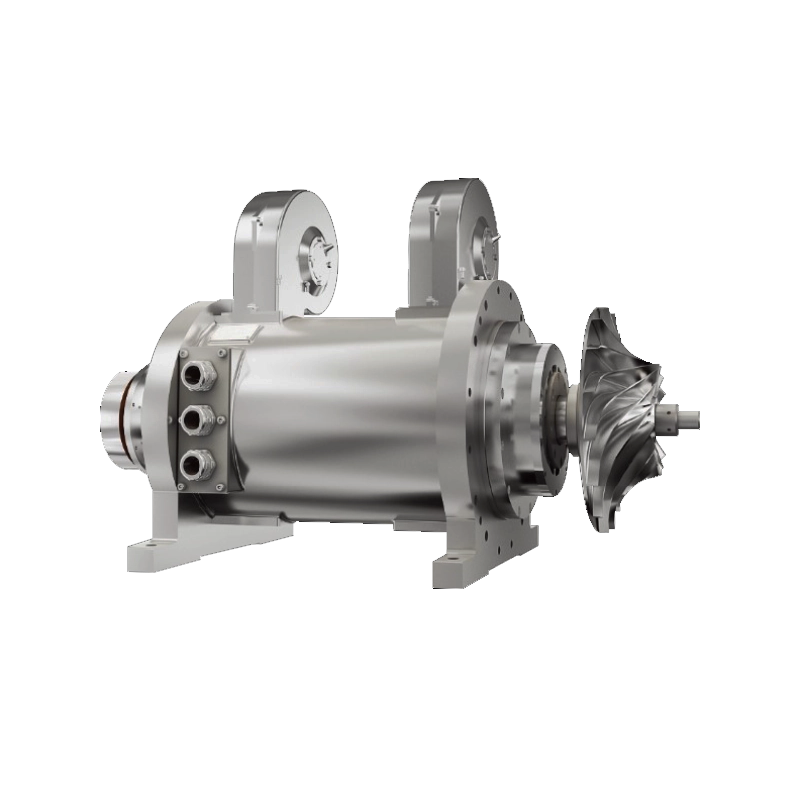

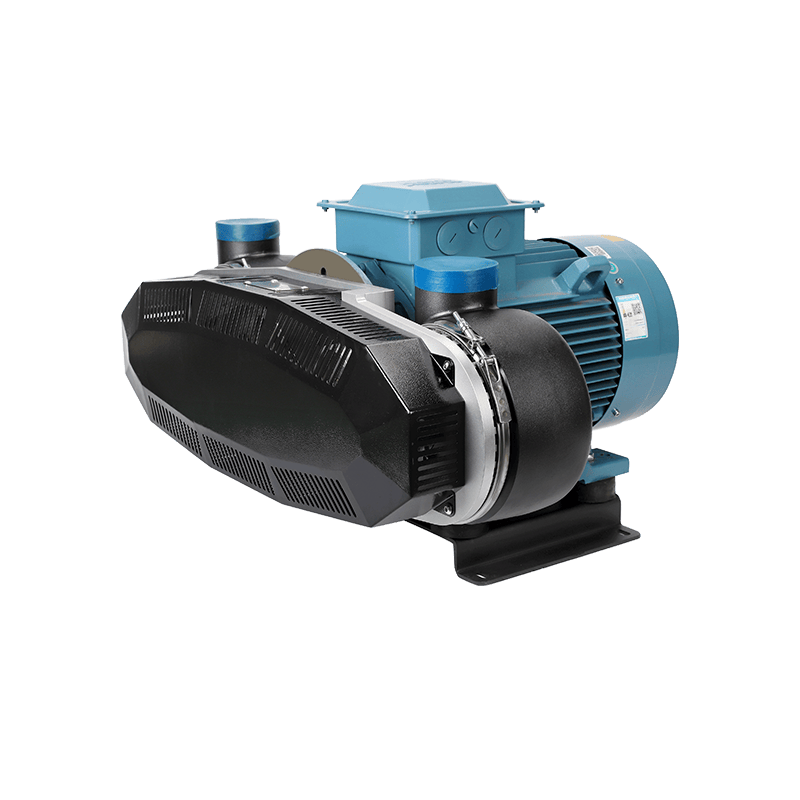

4. Through advanced wind blade design and powerful wind system, it is possible to quickly and effectively remove moisture from the surface of objects, greatly improving production efficiency. Reduce energy consumption while ensuring strong drying effect, and reduce operating noise

Smaller, creating a quieter working environment.

5. Compact structure, small footprint, flexible layout and installation according to the actual situation of the site, convenient for connection and collaborative work with other production equipment.

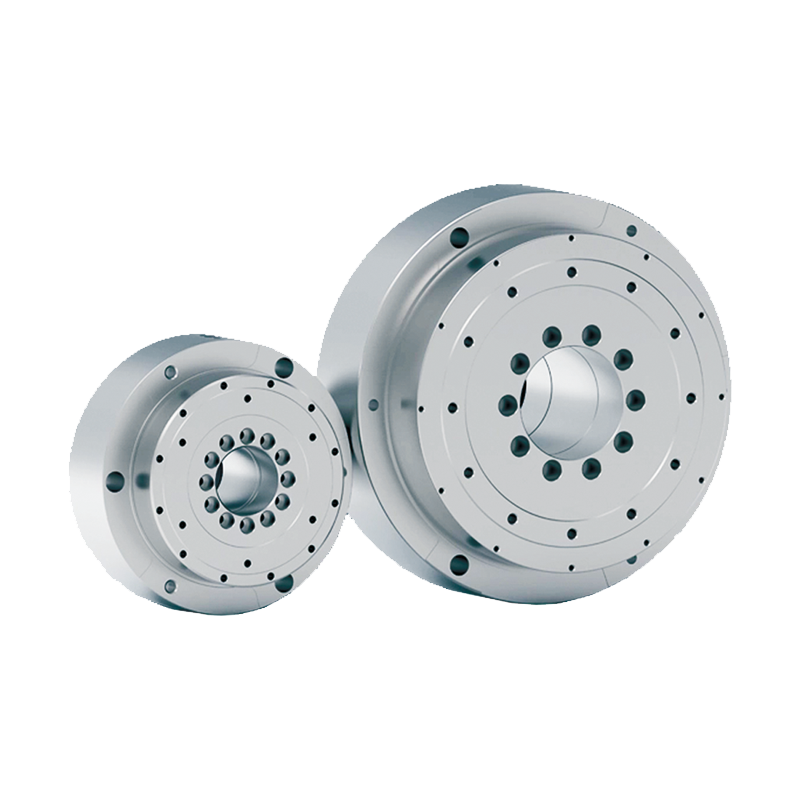

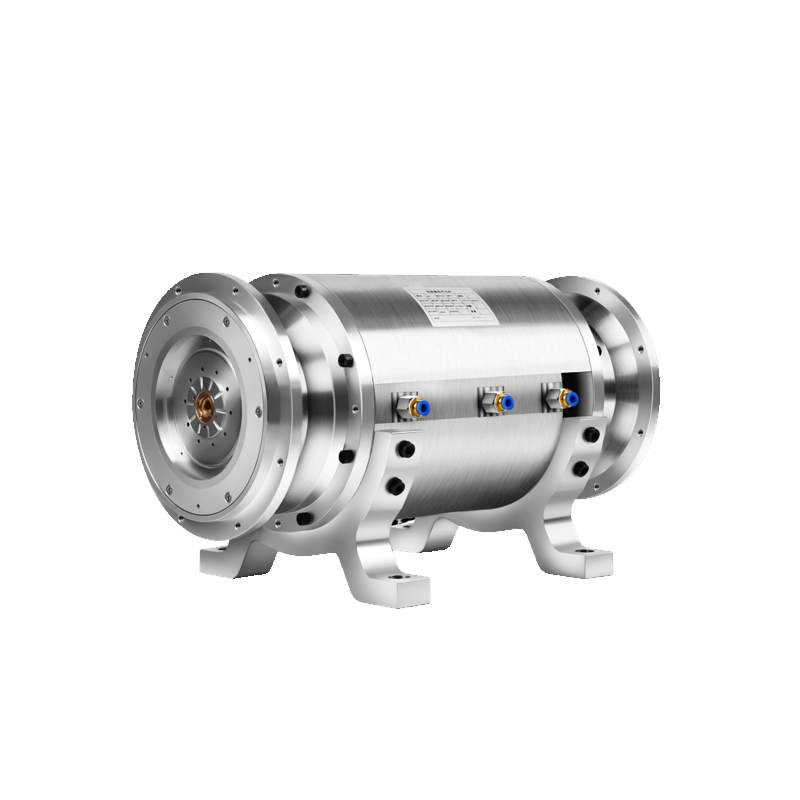

Related products

More>>Related News

More>>- Technological breakthrough and ap... 2024-11-02

- Small tips for using Smed high-sp... 2024-11-02

- Smart air suspension vs. magnetic... 2024-11-02

- Real time flow monitoring and adj... 2024-11-02

- Comparison of two types of vacuum... 2024-11-02

- Permanent magnet high-speed fan: ... 2024-11-02

- Efficient Energy Consumption Rati... 2024-11-02

- Machinery and Equipment: In depth... 2024-11-02

- Quick response guide for common f... 2024-11-02

- Coping with Environmental and Tem... 2024-11-02