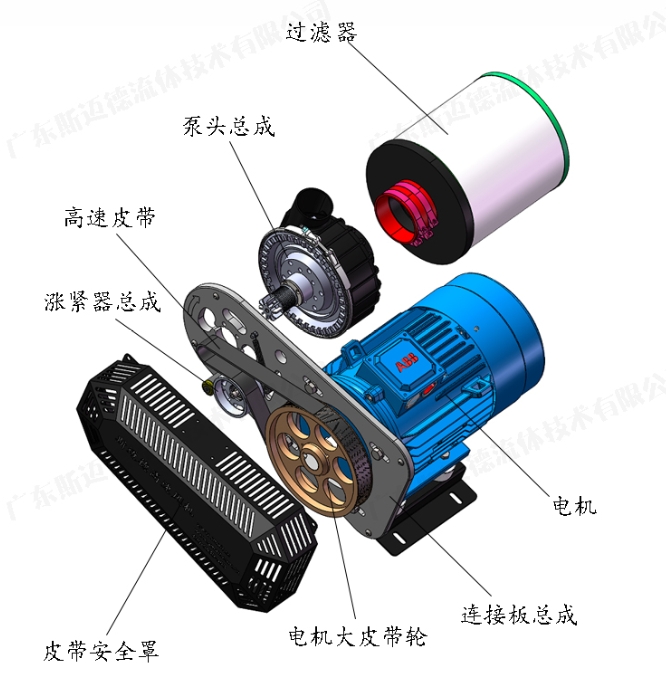

Have you encountered common faults during the operation of high-speed centrifugal blowers, such as surge, overload, bearing wear, impeller damage, motor failure, air outlet blockage, and abnormal vibration? The scope of these faults ranges from mechanical to electrical properties, and each type of fault poses a threat to the normal operation of the fan. The following provides a detailed explanation of the causes of these faults and targeted solutions:

1. Surge

& nbsp;reasonSurge is mainly caused by fluid dynamics instability, manifested as impeller stall of centrifugal blower, excessive inlet flow, system over damping, and rotor imbalance.

resolventTo avoid excessive import flow, adjust outlet resistance, improve system damping, regularly perform dynamic balancing treatment, and strengthen equipment maintenance, timely inspect and replace damaged parts to ensure the normal opening of the control valve.

2. Overload

& nbsp;reasonOverloading is usually caused by improper use by the user or inadequate maintenance of the equipment, such as motor overheating or burnout.

& nbsp;resolventRegularly inspect and replace improperly used components to ensure normal daily operation of the equipment, avoid prolonged overload operation, and perform timely maintenance to prevent damage.

3. Bearing wear

& nbsp;reasonLong term friction and wear can lead to bearing damage, insufficient lubricating oil or poor grease quality, as well as improper assembly of bearings, which can all cause bearing wear.

& nbsp;resolventRegularly clean, lubricate, and inspect bearings to ensure that the quality and supply of lubricating oil meet standards, while also ensuring the assembly accuracy and quality of bearings.

4. Damaged impeller

& nbsp;reasonDuring the operation of the equipment, the impeller is subject to the impact of high-speed airflow and high-temperature gas, which may cause wear or damage due to prolonged use.

resolventRegularly inspect the impeller to ensure its integrity, and promptly repair or replace it to ensure the normal operation of the equipment.

5. Motor malfunction

& nbsp;reasonOverheating of motor windings, cable disconnection, and other issues can cause motor failures, which are usually related to prolonged operation of the motor.

& nbsp;resolventRegularly inspect and maintain the motor, confirm that its cooling system is working properly, ensure the integrity of the windings and cables, and promptly address motor overheating issues.

6. Blockage of air outlet

& nbsp;reasonFailure to replace or clean filters, ducts, or other accessories in a timely manner may cause blockages in the air vents, resulting in poor equipment operation or shutdown.

& nbsp;resolventRegularly clean filters, conduits, and other accessories to ensure they are unobstructed.

7. Abnormal vibration

& nbsp;reasonIncorrect installation of equipment components or inadequate horizontal stability of the equipment can lead to abnormal vibrations.

& nbsp;resolventCheck whether each component of the equipment is installed correctly, detect the horizontal stability of the equipment, and promptly identify and resolve any faults caused by installation or stability.

In addition to promptly resolving the common faults mentioned above, it is also necessary to strengthen the daily maintenance and testing of equipment to ensure the stable and reliable operation of high-speed centrifugal blowers. For example, regularly record the status, air flow, wind pressure, sound, vibration, and other changes of the motor and each bearing. If any abnormal situation is found, immediately stop working and conduct disassembly inspection. Annual inspections are essential to ensure internal cleaning and inspection of lubricating oil conditions, and to replace them as necessary.

In summary, when dealing with faults in high-speed centrifugal blowers, operators and maintenance personnel should fully understand the causes of the faults and take corresponding measures to prevent and solve the problems. By regular maintenance, real-time monitoring, and quick and accurate handling of sudden failures, the operating efficiency and service life of the blower can be significantly improved. These faults and their solutions also reflect the importance of strictly following operating procedures during equipment operation, as well as the critical role of regular maintenance in ensuring the safe and normal operation of equipment.