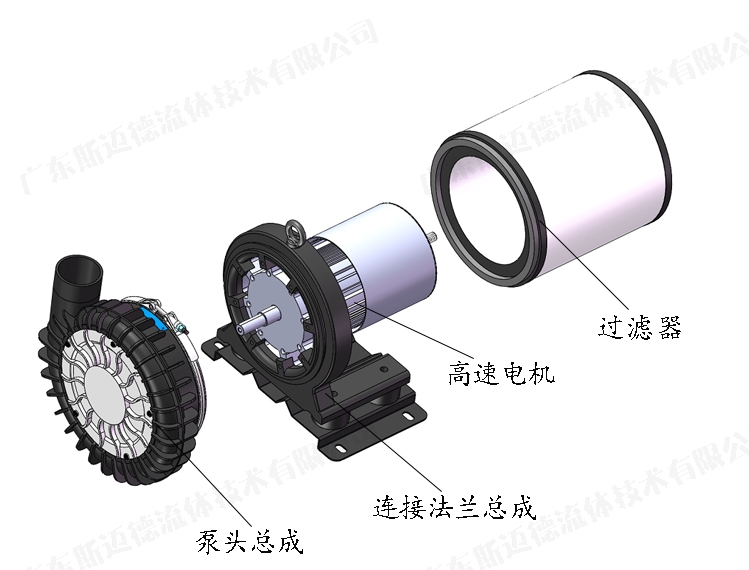

Permanent magnet high-speed fan is an efficient and energy-saving fan equipment widely used in the industrial field. Its installation and commissioning process is relatively complex, and it is necessary to follow the correct installation steps and precautions to ensure the normal operation and performance of the equipment. The following is a guide to the installation steps:

& nbsp; 1. Familiar with design drawings: Before installation, carefully read and understand the design drawings, materials, and instructions of the fan to ensure a thorough understanding of the equipment.

& nbsp; 2. Equipment inspection: Conduct equipment inspection on the fan, including specifications and form, impeller placement direction, normal clearance, air outlet orientation and shaft center distance inspection, operational flexibility, vibration and noise situation.

& nbsp; 3. Determine the installation reference line: The deviation between the installation reference line and the building axis should be less than/plusmn; 20mm, the deviation from the device's plane position should be less than/plus smn; 10mm, the deviation from the equipment elevation should be between -10 and 20mm.

& nbsp; 4. Ensure tight contact between the bearing seat and the base: The contact between the bearing seat and the base should be tight and uniform, with a local clearance of no more than 0.1mm. The longitudinal and transverse horizontal deviation of the bearing seat should not exceed 0.2/1000.

& nbsp; 5. Check the centerline of the casing: The deviation between the centerline of the casing and the centerline of the rotor should not exceed 2mm.

& nbsp; 6. Check the clearance between the journal and the bearing shell: The clearance between the journal and the bearing shell should not exceed 1.5/1000 of the journal diameter.

& nbsp; 7. Correct installation of valves: The installation of valves should be correct, and the flow direction of the medium should be consistent with the direction of the pointer on the valve.

& nbsp; 8. Check the lubricating oil system: When installing the lubricating oil system, instrument control system, and drive equipment, follow the installation requirements of each profession.

& nbsp; Overall, although the installation and commissioning of permanent magnet high-speed fans are complex, as long as the correct steps and precautions are followed, the normal operation and efficient performance of the equipment can be ensured.