Bottle drying production line

Wechat consulting

Details

Performance characteristics:

1. The plastic button type assembly line design ensures smooth and reliable conveying operation. Stainless steel protective strips are installed on both sides to ensure that there will be no bottle tipping or slipping during the drying process.

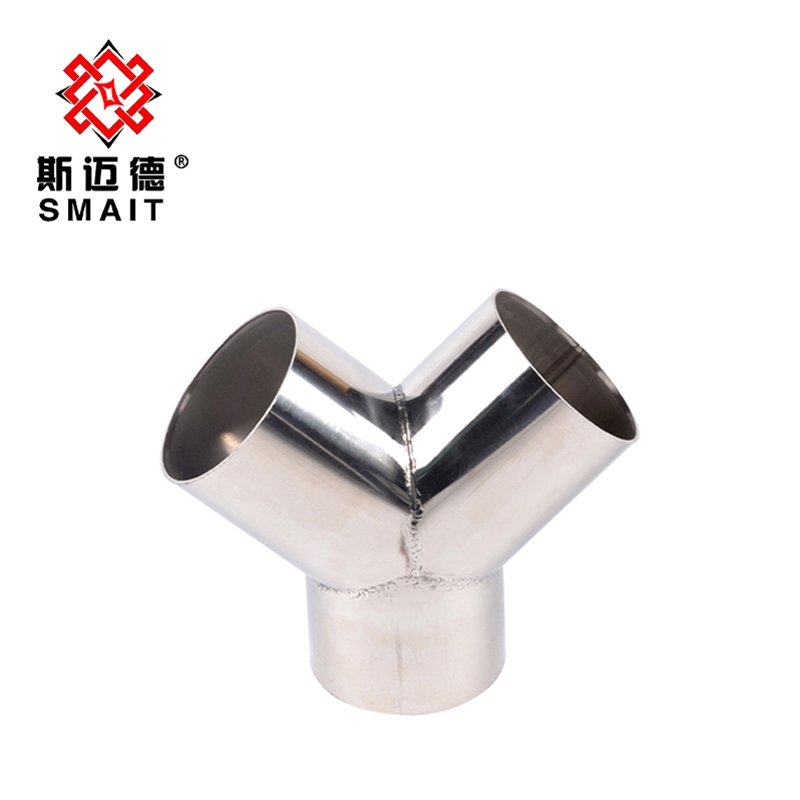

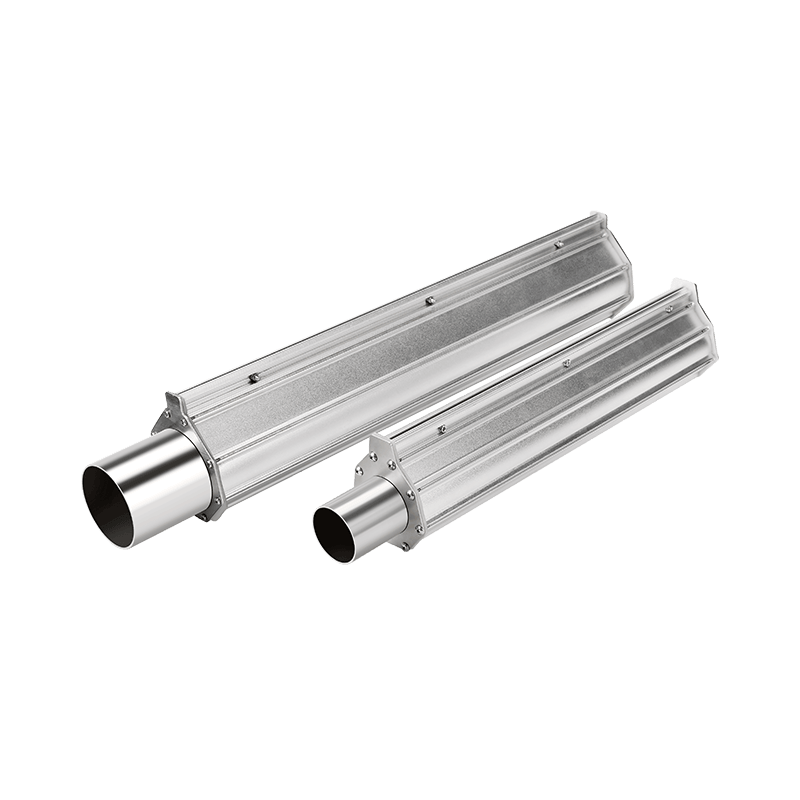

2. Using spider manifold air knives, the angle and height of each manifold can be easily adjusted manually to meet different usage scenarios and needs. Capable of handling products of different sizes with ease

Accurate adaptation, providing the best drying effect.

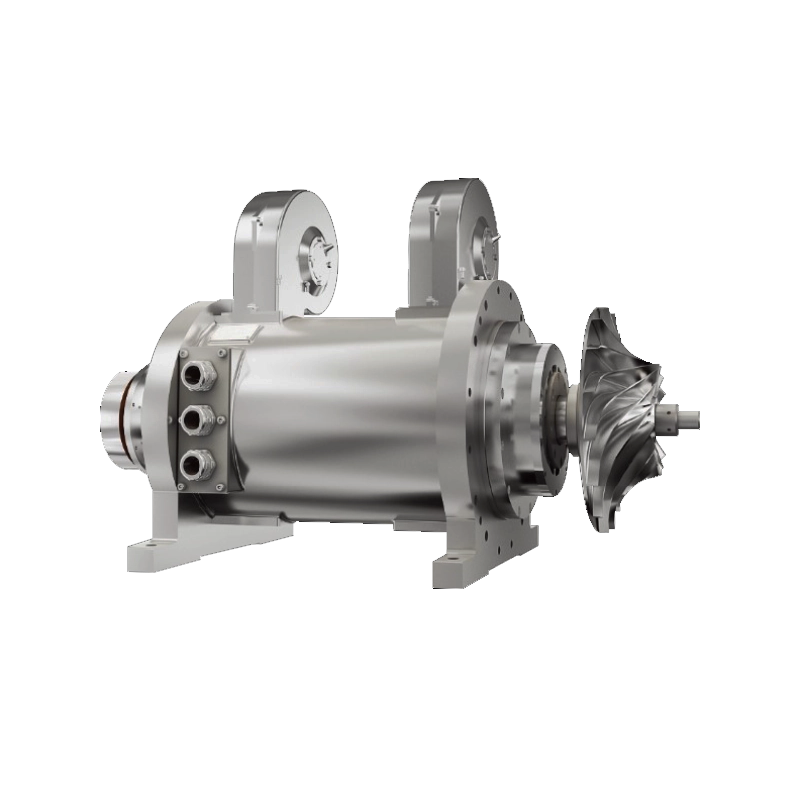

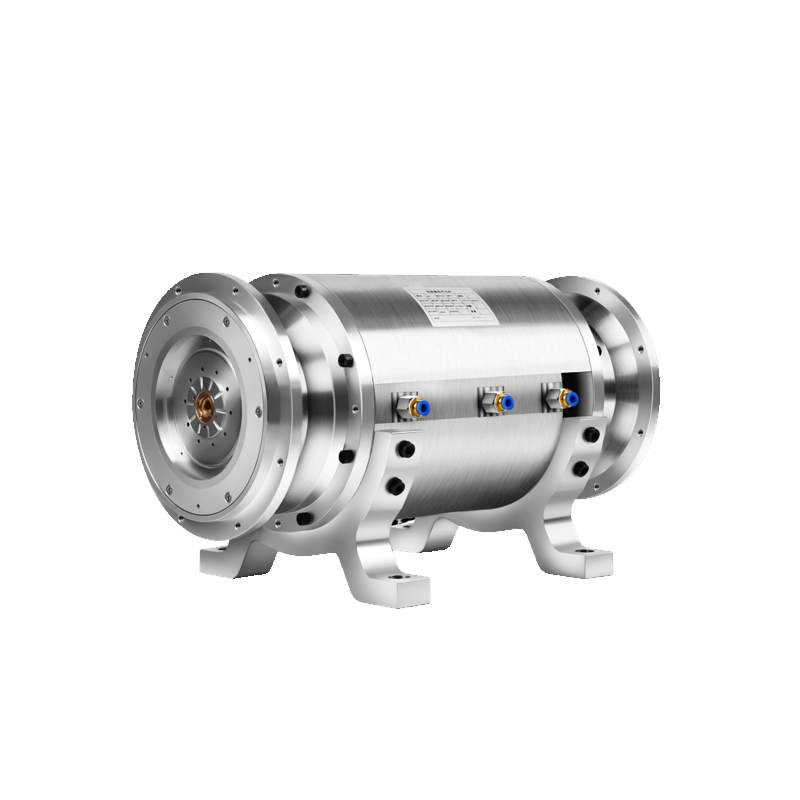

3. By using a frequency converter to precisely control and optimize the operation status of the motor, the starting current can be greatly reduced, reducing damage to the power grid and equipment

At the same time, it increases the service life of the fan and further achieves the goal of energy conservation and consumption reduction.

4. Through advanced spider manifold design and powerful wind system, the surface moisture of the bottle can be quickly and effectively removed. Reduce energy consumption while ensuring strong drying effect

Low operating noise, creating a relatively quiet working environment.

5. Compact structure, small footprint, flexible layout and installation according to the actual situation of the site, convenient for connection and collaborative work with other production equipment.

Related products

More>>Related News

More>>- Technological breakthrough and ap... 2024-11-02

- Small tips for using Smed high-sp... 2024-11-02

- Smart air suspension vs. magnetic... 2024-11-02

- Real time flow monitoring and adj... 2024-11-02

- Comparison of two types of vacuum... 2024-11-02

- Permanent magnet high-speed fan: ... 2024-11-02

- Efficient Energy Consumption Rati... 2024-11-02

- Machinery and Equipment: In depth... 2024-11-02

- Quick response guide for common f... 2024-11-02

- Coping with Environmental and Tem... 2024-11-02